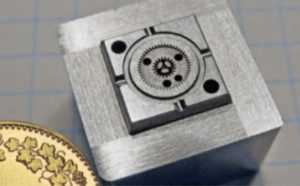

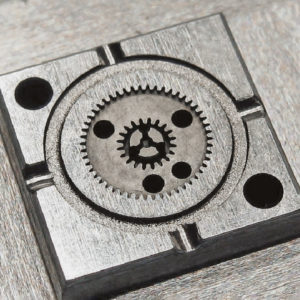

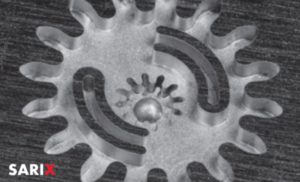

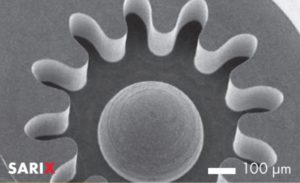

3D Micro EDM milling

Our technology enables 3D cavity milling without requiring form electrodes. We use high-precision solid carbide micro-electrodes and CAM-generated milling paths to achieve machining accuracy superior to die sinking.

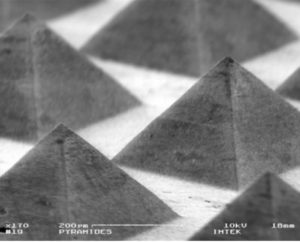

High surface finishing

The wide range of parameters and Micro-erosion energies of the PULSAR generator achieves surface qualities down to Ra 0.05 μm.

Micro electrode shaping

Cylindrical or shaped electrodes can be formed and mea-sured directly on the machine, eliminating any handling and clamping error.

Facts and results

3D Micro Milling of complexes forms with radius corner down to 3 microns

Perfect fins walls and microstructures profiles

Sharp wall straightness

Perfect bottom floor level control down to 2 micron

SAMPLE SELECTION

We meet your most demanding micro cavity challenges!

Contact us for a free sample test!